PVD-6

UHV Systems > Thin Film Deposition Systems > PVD Systems > PVD-6

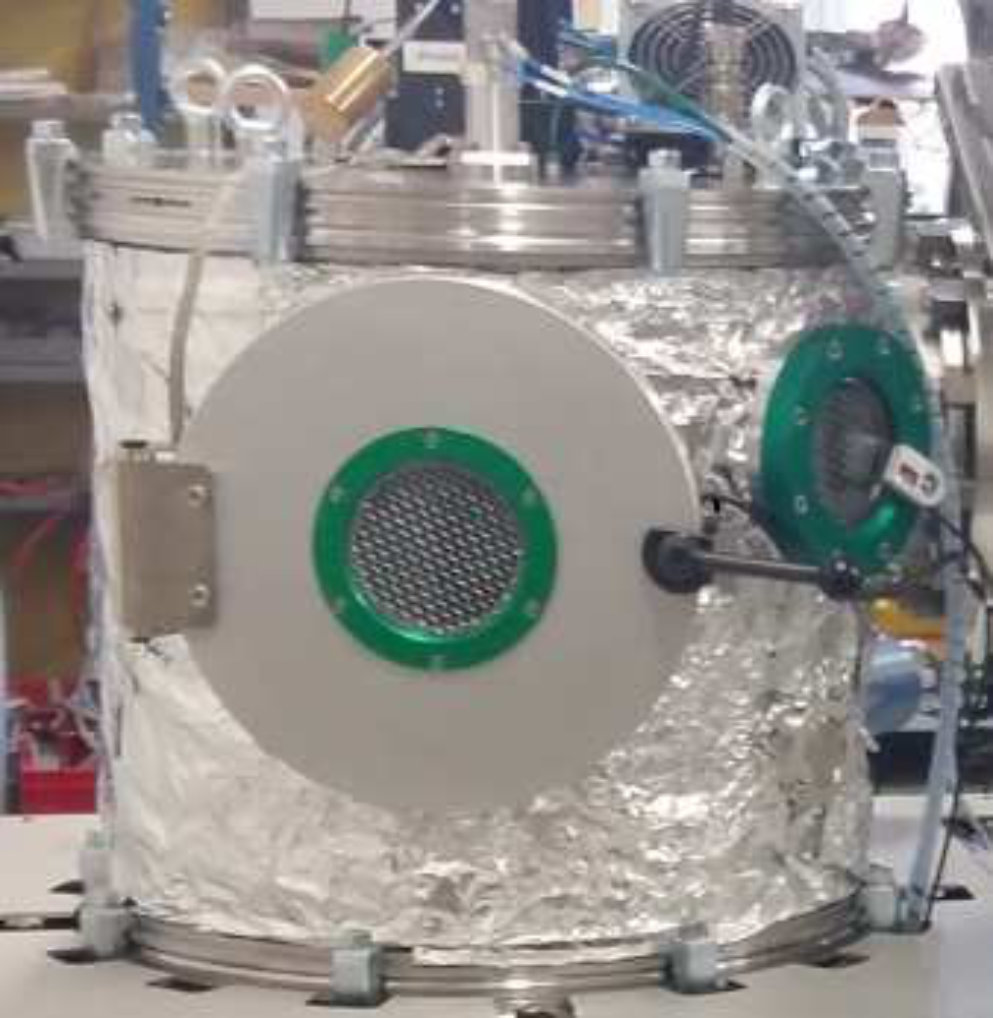

The PVD-6 is a physical vapor deposition system, dedicated to the Sputtering deposition process of materials. Its evolutionary design is particularly adapted to laboratory requirements in terms of every day applications, as its simplicity to use and its competitive price.

Specifications

| Thickness Homogeneity (@ working distance of approx. 100 mm) |

+/-3% |

| Thickness Reading Precision | 0.1 A |

| Deposition Rate Reading Precision | 0.01 A |

| Vacuum Base Pressure | 10-7 mbar or 10-8 mbar if LL |

| Pumping-down Time (10-6 mbar) | < 20 mins |

| Turbo pump | 550 L/s on N2 |

Core System features

- Stainless steel – 500 mm diameter cylindrical

- Fast Entry Frontal Door with viewport

- Sample holder for substrates up to 6” in diameter

- Water cooling to avoid excess heating

Magnetron Suttering

- 3” magnetron cathodes

- Integrated pneumatic shutters

- RF, DC or DC pulsed source power supplies

- Up to 6 cathodes in sputter up configuration

- Mass flow controller for gas line

- Pressure regulation by throttle valve

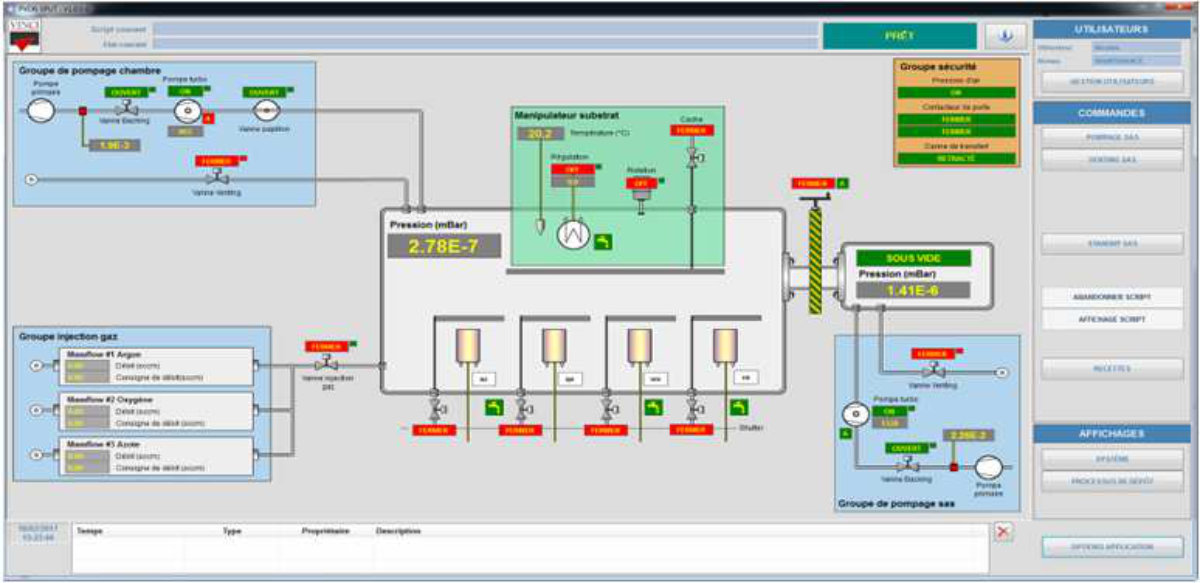

Easy to Use Software

The R&D orientated system can be supplied with an easy to use automation

software for full control of any deposition process.

Process supervision software with:

software for full control of any deposition process.

Process supervision software with:

- Vacuum Display

- Process Pressure display

- Pressure display

- Temperature control

- Valve/Shutter management

Fully & Semi Automatic modes

Recipe modes with traceability

User mode Access Levels

Safety management through a PLC:

- Interlock management for power supplies

- Automatic switching of the machine in safe mode

- Pressure, actuators and valves management

- First level securities management

Hardware :

Integrated PC with windows 7 connected to a PLC

Compatibility Matrix

| Configuration type | |

|---|---|

| PVD-6 | |

| SUBSTRATE HEATING (up to 350°C or 900°C) |

✓ |

| SUBSTRATE ACTIVE COOLING OR TEMPERATURE CONTROL |

✓ |

| SUBSTRATE ROTATION | ✓ |

| CATHODES 3″ |

Up to 6 |

| LOAD LOCK | ✓ |

| SAMPLE BIAS | ✓ |

| QUARTZ CONTROLLER | ✓ |

| THROTTLE VALVE | ✓ |

Get In Touch Today

Get in touch today to discuss your requirements, please contact us on