Vacuum Feedthroughs

We also have the facility to machine standard flanges to make a custom combination vacuum feedthrough to suit your project or requirements. Our wealth of experience in manufacturing techniques used to produce these items is your guarantee of unbeatable quality and our many years of experience in vacuum technology ensures the high quality needed for UHV applications. All of our Vacuum feedthroughs are TIG welded, the whole assembly is helium leak checked and issued with a certificate of conformity if requested.

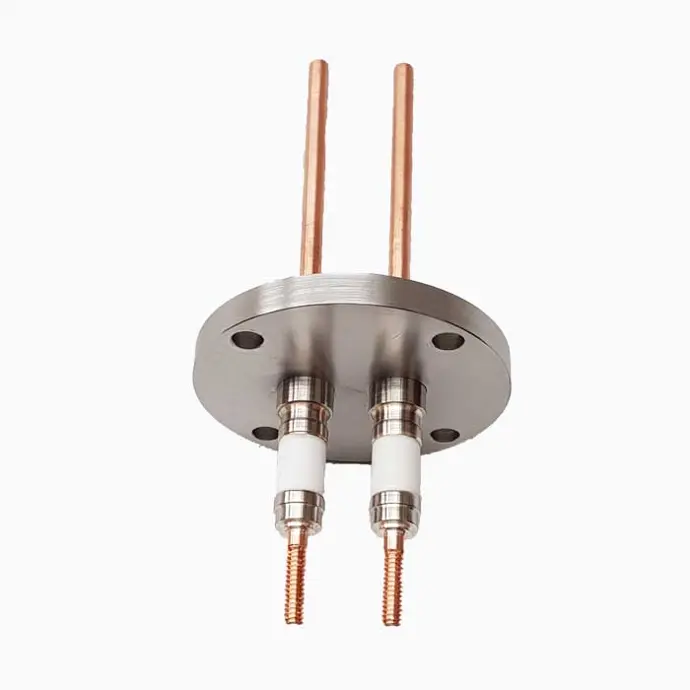

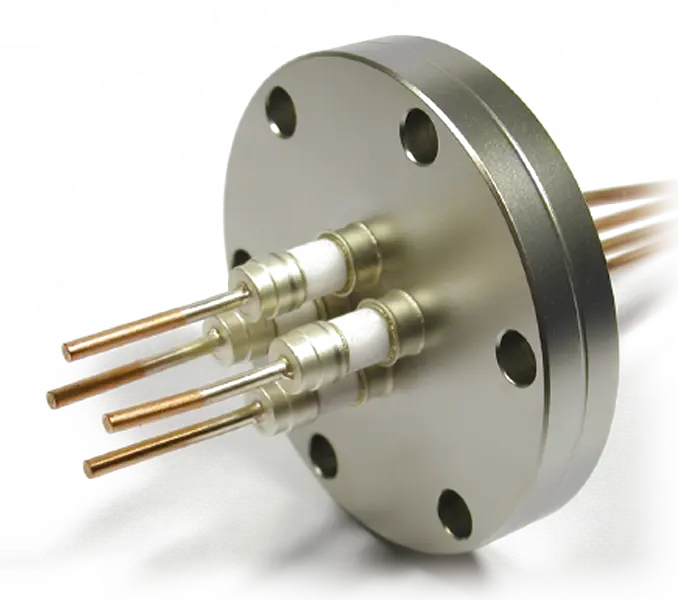

Feedthroughs are hermetic, vacuum sealed components and assemblies that have a conductor (wire, pins or solid rod) mounted into a ceramic to metal, glass to ceramic insulator joint to electrically isolate the current carrying conductors from the metallic mounting. They are suitable for high vacuum (HV) and ultra-high vacuum (UHV) environments and temperatures ranging from -270°C to 450°C.

Feedthroughs are used to transport a signal, electric current, temperature measurement or fibre optic into/from a Vacuum Vessel. Feedthroughs are supplied in weldable or flanged configurations. They are defined by the requirements of the intended use, installation, insulation and conductor material.

- Feedthroughs for low voltages (up to 12 kV)

- Water-cooled feedthroughs and RF feedthroughs

- High-voltage feedthroughs (20 to 100 kV)

ELECTRICAL POWER FEEDTHROUGHS

Take a look at our extensive range of ultra-high vacuum components

Electrical Power Feedthroughs provide transportation of electric current into and out of a Vacuum Vessel. Electrical Power Feedthroughs are available in a vast variety of vacuum applications, mounting flanges, voltages, and current carrying capacities. Electrical Feedthroughs are available from in the Voltage & Current range 1 kV 3 A to 8 kV 500 A

+44 (0) 1424 447726 [email protected]

Available Vacuum Feedthroughs

Multi-Pin Feedthroughs

Multi-pin Feedthroughs are feedthroughs with two or more conducting pins and are designed to accept a plug on the air side, but some feedthroughs allow for plugs on the vacuum side too.

Hermetically sealed Multi-pin Feedthroughs are designed primarily to provide instrumentation signals, voltage and/or current into/from a High-Vacuum (HV) or Ultra-high Vacuum (UHV) Vacuum Vessel.

- Voltages up to 12 kV DC

- Currents up to 40 A

- Temperature range from -269°C to 450°C

- Internal pressure 1×10-10 mbar up to 41 bar (600 psig)

- Up to 50 pins/conductors

Instrument Feedthroughs

Instrument Feedthroughs are designed to transfer low current, low or high voltage signals from low or high impedance into/from a Vacuum Vessel. They have one or multiple conductors (wire) with a standard electrical plug/socket on the air-side. Some types are also suitable for having connections on the vacuum side.

Co-Axial Feedthroughs

Co-axial Feedthroughs are connectors that consist of two concentric conductors: a central inner conductor serves as a current carrying contact and is surrounded by and insulated from an outer tubular conductor that serves as an electromagnetic shield. The outside conductor is usually at ground potential but in some product variations may be floated off ground by employing an additional insulating ring. The outer conducting surface can prevent radio frequency noise from passing to or from the central conductor.

The standard coaxial plug options are BNC, MHV, various SHVs, N, Microdot, SMA, and SMB.

Industry Standard Specifications

- Grounded shield or floating shield configuration

- High frequency impedance matched connectors as SMA, BNC, Type N and HN

- Connectors are sold with or without air side plugs

Get In Touch Today

Get in touch today to discuss your requirements, please contact us on

+44 (0) 1424 447726 [email protected]

Thermocouple Feedthroughs

Thermocouple Feedthroughs are used to measure temperature inside a Vacuum Vessel. Thermocouples are manufactured with differing thermocouple materials or compensating material. The differing materials transmit electromotive force (EMF) generated by the heat application to the thermocouple hot junction (bead joint) transmitted from the inside of a Vacuum Vessel.

External temperature measurement controllers evaluate the strength of the electromotive force that is proportional to the temperature at the hot junction and displays the temperature.

Typical ANSI-standardized thermocouple material pairs are listed in the table below.

| Thermocouple Type | Thermocouple Materials | Polarity | Measurable Temperature Range (°C) |

| T | Copper Constantan | + – | -200 to 350 |

| K | hromel® Alumel | + – | -200 to 1250 |

| R/S | Platinum 13/10 % Rhodium* Platinum | + _ | 0 to 1450 |

| J | Iron Constantan | + _ | 0 to 750 |

| E | Chromel® Constantan | + _ | -200 to 900 |

| C | Wolfram 5 % Rhenium Wolfram 26 % Rhenium | + _ | 0 to 2315 |

Contact Us

You can contact UltraHighVacuum.com in multiple ways. You can either fill out the contact form, and we’ll get back to you as soon as possible. Alternatively, use any of the methods below to contact us.

UltraHighVacuum.com

Unit 7, Haywood Way,

Hastings, East Sussex

TN35 4PL

England

Express delivery for the UK & Europe

Excellent customer care guaranteed

ISO 9001 approved company

Highest quality & performance assured