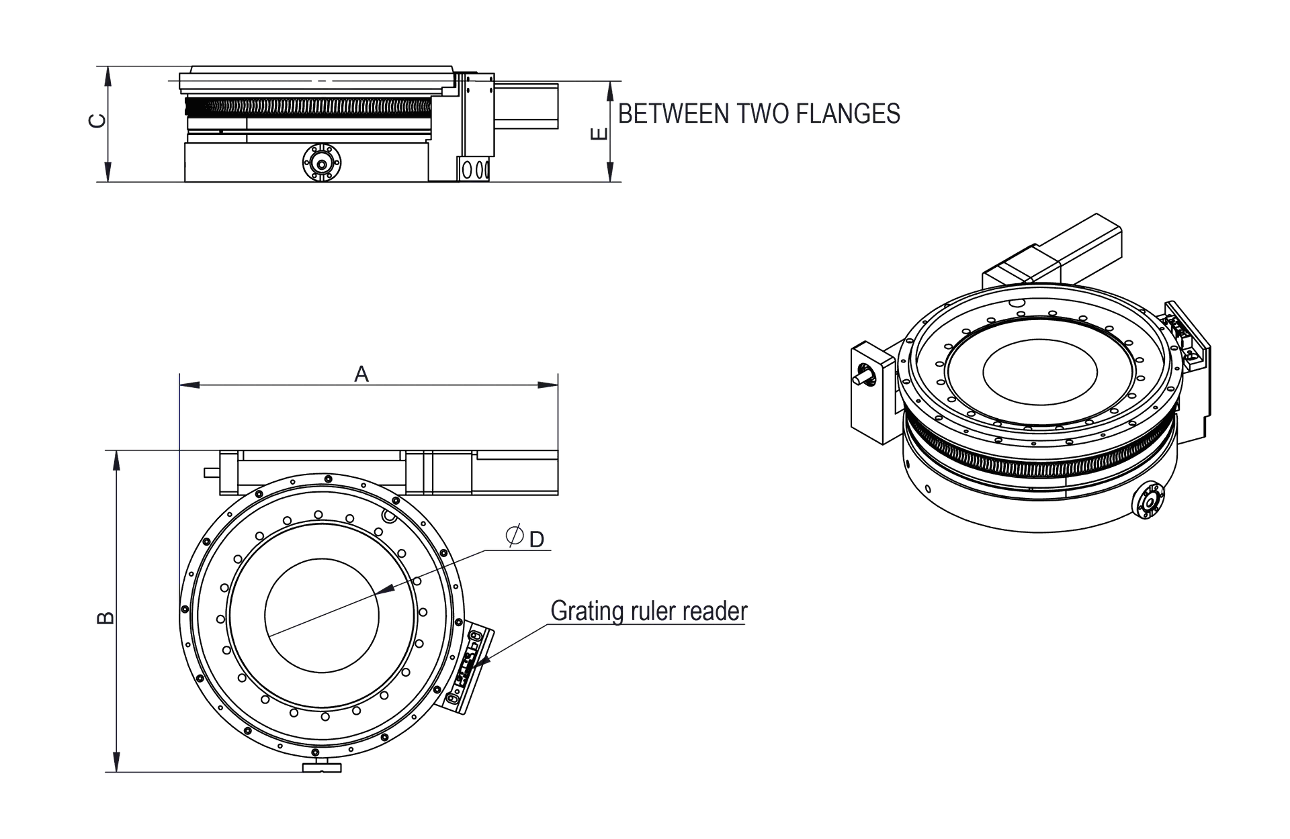

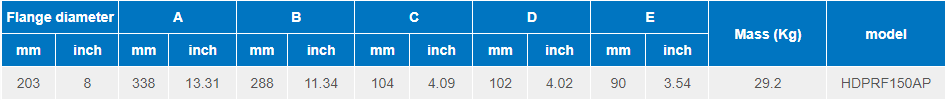

High-precision Differentially Pumped Rotary Feedthrough (Optical Encoder) 360 Degree Rotation, CF203 Flange

High-precision differential rotary drives by using crossed roller bearings, the accuracy and stiffness of rotary drives can be greatly improved. The product structure has a complete inner and outer ring, and the bearing can be directly mounted on the rotating fixed end without any fixing plate and housing. Therefore, while maintaining the distance between the rotary drive rotating body and the fixed flange, it is possible to increase the bearing thickness or the size of the rolling elements in the bearing, and the performance is almost completely unaffected by the bearing installation. This allows a photoelectric encoder to be installed in the compact ultra-high vacuum rotary drive, using a servo motor to drive the worm gear and a precise rotary encoder for position feedback, making the compact ultra-high vacuum rotary drive with high precision. Larger balls increase the rigidity of the UHV rotary drive.

• Servo motor driver

• High-precision Crossed Roller Bearings

• Rotation range: ±175°

• Carry heavy loads: >2000kg

• Optical encoder, resolution: ≤0.0001°

• One stage differential pumping for UHV Performance

• Mounting flange on both sides: CF flange, tapped hole